OTHER PRODUCTS

Have Questions?

Get in touch with us today to avail the best quote for your requirement. We offer top quality metal products, competitive pricing and quick delivery.

Copper Nickel Pipes & Tubes

ASTM B466 UNS C70600 Seamless & Welded Pipes & Tubes, Copper Nickel UNS C71500 Square Tubes Stockist, 90-10 Cupro-Nickel Rectangular Pipes, Copper Nickel 70/30 Tubes, Cu-Ni Welded Pipes & Tubes, Cupro Nickel Round Pipe, Custom Cupro Nickel Pipe, Cupro Nickel ERW Pipe Supplier in India.

Overview

Dhodi Metal Industries is the most renowned and well-known manufacturer, exporter, and supplier of the highest-quality copper nickel pipes and tubes. We offer a large variety of shapes, sizes, grades, and specifications for these pipes and tubes. Additionally, we offer them in a variety of bespoke sizes based on the customers’ demands.

We produce a variety of these pipes and tubes, such as Cupronickel Welded Pipes & Tubes, Cupronickel Seamless Pipes & Tubes, and more. Cupronickel 70/30 Pipes & Tubes, Cupronickel 90/10 Pipes & Tubes, and more material grades are available for all of these forms. Our specialty is offering these pipes and tubes in both standard and bespoke sizes.

Cu-Ni Pipes & Tubes has some great features to offer such as Easy to use, Top quality, Low maintenance, Low prices, Longer life, Highly durable, Fine finish, Rust free and more. Copper Nickel Welded Tubes are perfect for applications where superior strength and better corrosion resistance is needed. The Cupro Nickel Seamless Pipe has a 20% higher load-bearing capacity than other pipe types.

90/10 Copper Nickel (CuNi 90/10) Pipes & Tubes: Contains 90% copper and 10% nickel, plus trace elements like iron and manganese for additional strength and corrosion resistance.

70/30 Copper Nickel (CuNi 70/30) Pipes & Tubes: With 70% copper and 30% nickel, this grade offers even greater corrosion resistance, often used in more demanding marine and industrial applications.

Specification Of Copper Nickel Pipes & Tubes

| Specifications | ASTM B 466 ASME SB 466 / ASTM B 467 ASME SB 467 |

| Dimensions | ASTM, ASME and API |

| Graded | Cu-Ni 70/30 (UNS C70600), Cu-Ni 90/10 (UNS C71500) |

| Size | 1/2″ TO 6′ IN OD & NB IN Various SWG & SCH |

| Specialized in | Large Diameter Size |

| Type | Seamless / ERW / Welded / Fabricated / LSAW |

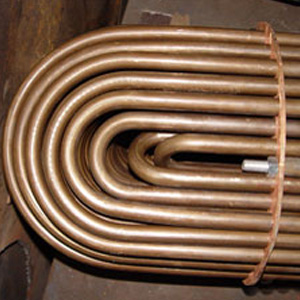

| Form | Rectangular, Boiler, Hydraulic, Round, Coil, Square, Straight or ‘U’ bent Tubes, Hollow, LSAW Tubes Etc. |

| Length | Single Random, Double Random & Cut Length. |

| End | Plain End, Beveled End, Treaded |

Cu-Ni Pipes & Tubes Types

-

- Copper Nickel Round Pipes & Tubes

-

- Copper Nickel Square Pipes & Tubes

-

- Copper Nickel Seamless Pipes & Tubes

-

- Copper Nickel Capillary Tubes

-

- Copper Nickel Hydraulic Tubes

-

- Copper Nickel Heat Exchanger Tubes

-

- Copper Nickel Coil Tubing

-

- Copper Nickel Boiler Tubing

Copper Nickel Pipes & Tubes Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS |

| Copper Nickel 90/10 | 2.0872 | C70600 |

| Copper Nickel 70/30 | 2.0882 | C71500 |

Copper Nickel Pipes & Tubes Chemical Composition

| Grade | Cu | Pb | Mn | Fe | Zn | Ni |

| Cupro Nickel 90/10 | 88.6 min | .05 max | 1.0 max | 1.8 max | 1 max | 9-11 max |

| Cupro Nickel 70/30 | 65.0 min | .05 max | 1 max | 0.4-1.0 | 1 max | 29-33 |

Cu-Ni Pipes & Tubes Physical Properties

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Cu-Ni 90/10 | 0.323 lb/in3 at 68 F | 2260 F | 50000 psi | 20000 psi | 30 % |

| Cu-Ni 70/30 | 0.323 lb/in3 at 68 F | 2260 F | 50000 psi | 20000 psi | 30 % |

Cupro Nickel Pipes Size Chart

| Outside Diameter | Wall Thickness Chart | THEORETICAL WEIGHT | |||

| Nominal Size (inch) | Actual Size ( mm) | Actual WT (mm) | Actual WT (inch) | Kg/m | Lb/Ft |

| Copper Nickel Seamless Pipes | |||||

| 1/8 | 10,29 | 1,47 | 0,058 | 0,36 | 0,24 |

| 1/4 | 13,72 | 1,65 | 0,065 | 0,56 | 0,38 |

| 3/8 | 17,15 | 1,65 | 0,065 | 0,72 | 0,48 |

| 1/2 | 21,34 | 1,65 | 0,065 | 0,91 | 0,61 |

| 3/4 | 26,67 | 1,65 | 0,065 | 1,16 | 0,78 |

| 1 | 33,4 | 1,65 | 0,065 | 1,47 | 0,99 |

| 1 1/4 | 42,16 | 1,83 | 0,72 | 2,07 | 1,39 |

| 1 1/2 | 48,26 | 1,83 | 0,72 | 2,39 | 1,60 |

| 2 | 60,32 | 2,11 | 0,083 | 3,45 | 2,32 |

| 2 1/2 | 73,03 | 2,11 | 0,083 | 4,20 | 2,82 |

| 3 | 88,9 | 2,41 | 0,095 | 5,85 | 3,93 |

| 3 1/2 | 101,6 | 2,41 | 0,095 | 6,71 | 4,51 |

| 4 | 114,3 | 2,77 | 0,109 | 8,68 | 5,83 |

| 5 | 141,3 | 3,18 | 0,125 | 12,34 | 8,29 |

| 6 | 168,3 | 3,4 | 0,134 | 15,75 | 10,58 |

| 8 | 219,1 | 3,4 | 0,134 | 20,60 | 13,84 |

| Cupro Nickel Seamless Pipes OR Cu-ni Welded Pipes | |||||

| 10 | 273,05 | 3,4 | 0,134 | 25,75 | 17,30 |

| 12 | 323,9 | 3,96 | 0,156 | 35,58 | 23,91 |

| 14 | 355,6 | 4,19 | 0,165 | 41,35 | 27,79 |

| 16 | 406,4 | 4,19 | 0,165 | 47,33 | 31,81 |

| 18 | 457 | 4,57 | 0,18 | 58,07 | 39,02 |

| 20 | 508 | 4,57 | 0,18 | 64,62 | 43,42 |

| Cu-Ni Welded Pipes | |||||

| 24 | 610 | 4,57 | 0,18 | 77,71 | 52,22 |

| 30 | 762 | 6,35 | 0,25 | 134,77 | 90,56 |

Cupro Nickel Tubes Size Chart

| Wall Size | Sizes (Outer Diameter) |

| .010 | 1/16″ , 1/8″ , 3/16″ |

| .020 | 1/16″ , 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ |

| .012 | 1/8″ |

| .016 | 1/8″ , 3/16″ |

| .028 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 3/4″ , 1″ , 1 1/2″ , 2″ |

| .035 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 7/16″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .049 | 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/8″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .065 | 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 3/4″ , 2″ , 2 1/2″ , 3″ |

| .083 | 1/4″ , 3/8″ , 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 7/8″ , 2″ , 2 1/2″ ,3″ |

| .095 | 1/2″ , 5/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .109 | 1/2″ , 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .120 | 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 2 1/4″ , 2 1/2″ , 3″ |

| .125 | 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 3″ , 3 1/4″ |

| .134 | 1″ |

| .250 | 3″ |

| .375 | 3 1/2″ |

Copper Nickel Pipes & Tubes Weight Chart

| Nominal Pipe Size | WT | O.D. | Weight | Weight | |||

| millimeter | in | in | millimeter | kilogram/Meter | Sched | Lb/ft | |

| 1/2″ | 2.769 | 0.0109 | 0.0840 | 21 | 1.268 | 40 STD | 0.0851 |

| 3.734 | 0.0147 | 1.621 | 80 STD | 1.088 | |||

| 3/4″ | 2.870 | 0.0113 | 1.050 | 27 | 1.684 | 40 STD | 1.131 |

| 3.912 | 0.0154 | 2.195 | 80 STD | 1.474 | |||

| 1″ | 3.378 | 0.0133 | 1.315 | 33 | 2.501 | 40 STD | 1.679 |

| 4.547 | 0.0179 | 3.325 | 80 STD | 2.172 | |||

| 1 1/4″ | 3.556 | 0.0140 | 1.660 | 42 | 3.385 | 40 STD | 2.273 |

| 4.851 | 0.0191 | 4.464 | 80 STD | 2.997 | |||

| 1 1/2″ | 3.683 | 0.0145 | 1.900 | 48 | 4.048 | 40 STD | 2.718 |

| 5.080 | 0.0200 | 5.409 | 80 STD | 3.361 | |||

| 2″ | 3.912 | 0.0154 | 2.375 | 60 | 5.441 | 40 STD | 3.653 |

| 5.537 | 0.0218 | 7.480 | 80 STD | 5.022 | |||

| 2 1/2″ | 5.516 | 0.0203 | 2.875 | 73 | 8.629 | 40 STD | 5.793 |

| 7.010 | 0.0276 | 11.411 | 80 STD | 7.661 | |||

| 3″ | 5.486 | 0.0216 | 3.500 | 89 | 11.284 | 40 STD | 7.576 |

| 7.620 | 0.0300 | 15.272 | 80 STD | 10.0253 | |||

| 4″ | 6.020 | 0.0237 | 4.500 | 114 | 16.073 | 10.0790 | |

| 8.560 | 0.0337 | 22.318 | 14.983 | ||||

| 6″ | 4.775 | 0.0188 | 6.625 | 168 | 19.252 | 12.924 | |

| 5.516 | 0.0203 | 20.0739 | 13.923 | ||||

| 5.563 | 0.0219 | 22.318 | 14.983 | ||||

| 6.350 | 0.0250 | 25.354 | 17.021 | ||||

| 7.112 | 0.0280 | 58.263 | 40 STD | 18.974 | |||

| 7.925 | 0.0312 | 31.334 | 21.036 | ||||

| 9.525 | 0.0375 | 37.285 | 25.031 | ||||

| 10.0973 | 0.0432 | 42.561 | 80 XHY | 28.573 | |||

| 12.700 | 0.0500 | 48.719 | 32.708 | ||||

| 8″ | 4.775 | 0.0188 | 8.625 | 219 | 25.233 | 16.940 | |

| 5.156 | 0.0203 | 27.198 | 18.259 | ||||

| 5.563 | 0.0219 | 29.286 | 19.661 | ||||

| 6.350 | 0.0250 | 33.308 | 20 | 22.361 | |||

| 7.036 | 0.0277 | 36.786 | 30 | 24.696 | |||

| 8.179 | 0.0322 | 42.352 | 40 | 28.554 | |||

| 9.525 | 0.0375 | 49.216 | 33.041 | ||||

| 10.0312 | 0.0406 | 53.085 | 60 | 35.638 | |||

| 12.700 | 0.0500 | 64.627 | 80 XHY | 43.388 | |||

| 10″ | 4.775 | 0.0188 | 10.0750 | 273 | 31.588 | 21.207 | |

| 5.563 | 0.0219 | 36.689 | 24.631 | ||||

| 6.350 | 0.0250 | 41.759 | 20 | 28.035 | |||

| 7.798 | 0.0307 | 51.002 | 30 | 34.240 | |||

| 8.738 | 0.0344 | 56.946 | 38.231 | ||||

| 9.271 | 0.0365 | 63.301 | 40 STD | 40.0483 | |||

| 11.125 | 0.0438 | 71.852 | 48.238 | ||||

| 12.700 | 0.0500 | 81.530 | 60 XHY | 54.735 | |||

| 15.088 | 0.0594 | 95.969 | 80 | 64.429 | |||

| 12″ | 4.775 | 0.0188 | 12.750 | 324 | 37.570 | 25.222 | |

| 5.563 | 0.0219 | 43.657 | 29.309 | ||||

| 6.350 | 0.0250 | 49.713 | 33.375 | ||||

| 7.137 | 0.0281 | 55.739 | 37.420 | ||||

| 7.925 | 0.0312 | 61.735 | 41.445 | ||||

| 9.525 | 0.0375 | 73.824 | 49.562 | ||||

| 10.0312 | 0.0406 | 79.727 | 53.525 | ||||

| 12.700 | 0.0500 | 97.438 | 65.415 | ||||

| 14.275 | 0.0562 | 108.966 | 73.154 | ||||

| 14″ | 4.775 | 0.0188 | 14.000 | 356 | 41.308 | 27.732 | |

| 5.563 | 0.0219 | 48.012 | 32.233 | ||||

| 6.350 | 0.0250 | 54.685 | 20 | 36.713 | |||

| 7.137 | 0.0281 | 61.327 | 41.172 | ||||

| 7.925 | 0.0312 | 67.939 | 45.611 | ||||

| 9.525 | 0.0375 | 81.281 | STD | 54.568 | |||

| 11.125 | 0.0438 | 94.498 | 40 | 63.441 | |||

| 12.700 | 0.0500 | 107.381 | XHY | 72.090 | |||

| 15.875 | 0.0625 | 132.983 | 89.278 | ||||

| 16” | 4.775 | 0.0188 | 16.000 | 406 | 47.290 | 21.748 | |

| 5.563 | 0.0219 | 54.980 | 36.910 | ||||

| 6.350 | 0.0250 | 62.639 | 10 | 42.053 | |||

| 7.137 | 0.0281 | 70.0268 | 47.174 | ||||

| 7.925 | 0.0312 | 77.866 | 20 | 52.275 | |||

| 8.738 | 0.0344 | 85.677 | 57.519 | ||||

| 9.525 | 0.0375 | 93.213 |

30 STD |

62.578 | |||

| 11.125 | 0.0438 | 108.433 | 72.797 | ||||

| 12.700 | 0.0500 | 123.289 |

40 XHY |

82.770 | |||

| 18″ | 5.563 | 0.0219 | 18.000 | 457 | 61.948 | 41.588 | |

| 6.350 | 0.0250 | 70.0593 | 47.393 | ||||

| 7.137 | 0.0281 | 79.208 | 53.176 | ||||

| 7.925 | 0.0312 | 87.792 | 20 | 58.939 | |||

| 9.525 | 0.0375 | 105.144 | STD | 70.0588 | |||

| 11.125 | 0.0438 | 122.369 | 30 | 82.152 | |||

| 12.700 | 0.0500 | 139.198 | XHY | 93.450 | |||

| 14.275 | 0.0562 | 155.904 | 40 | 104.666 | |||

| 15.875 | 0.0625 | 172.754 | 115.978 | ||||

| 20″ | 6.350 | 0.0250 | 20.0000 | 508 | 78.547 | 52.733 | |

| 7.163 | 0.0282 | 88.458 | 59.386 | ||||

| 7.925 | 0.0312 | 97.719 | 65.604 | ||||

| 9.525 | 0.0375 | 117.075 | 20 STD | 78.598 | |||

| 11.125 | 0.0438 | 136.305 | 91.508 | ||||

| 12.700 | 0.0500 | 155.106 | 30 XHY | 104.130 | |||

| 15.088 | 0.0594 | 183.378 | 40 | 123.110 | |||

| 15.875 | 0.0625 | 192.640 | 129.328 | ||||

| 17.475 | 0.0688 | 211.368 | 141.901 | ||||

| 24″ | 6.350 | 0.0250 | 24.000 | 610 | 94.456 | 63.413 | |

| 7.137 | 0.0281 | 106.029 | 71.183 | ||||

| 7.925 | 0.0312 | 117.573 | 18.932 | ||||

| 9.525 | 0.0375 | 140.0938 | 20 STD | 64.618 | |||

| 11.125 | 0.0438 | 164.176 | 110.0219 | ||||

| 12.700 | 0.0500 | 186.923 | XHY | 125.490 | |||

| 15.875 | 0.0625 | 232.410 | 156.028 | ||||

| 17.475 | 0.0688 | 255.148 | 40 | 171.293 | |||

| 19.050 | 0.0750 | 277.401 | 186.233 | ||||

| 30″ | 6.350 | 0.0250 | 30.0000 | 762 | 118.318 | 79.433 | |

| 7.137 | 0.0281 | 132.851 | 89.189 | ||||

| 7.925 | 0.0312 | 147.353 | 10 | 98.925 | |||

| 9.525 | 0.0375 | 176.731 | STD | 118.648 | |||

| 11.125 | 0.0438 | 205.983 | 138.286 | ||||

| 12.700 | 0.0500 | 234.647 | 20 XHY | 157.530 | |||

| 15.875 | 0.0625 | 292.066 | 30 | 196.078 | |||

| 17.475 | 0.0688 | 320.0817 | 215.380 | ||||

| 19.050 | 0.0750 | 348.988 | 234.293 | ||||

| 36″ | 6.350 | 0.0250 | 36.000 | 914 | 142.180 | 95.453 | |

| 7.137 | 0.0281 | 159.672 | 107.196 | ||||

| 7.925 | 0.0312 | 177.133 | 10 | 118.918 | |||

| 9.525 | 0.0375 | 215.525 | STD | 142.678 | |||

| 11.125 | 0.0438 | 247.790 | 166.353 | ||||

| 12.700 | 0.0500 | 282.372 | 20 XHY | 198.570 | |||

| 15.875 | 0.0625 | 351.723 | 236.128 | ||||

| 17.475 |

0.0688 |

386.487 | 259.467 | ||||

| 19.050 |

0.0750 |

420.0576 | 282.353 | ||||

| 42″ | 7.925 | 0.0312 | 42.000 | 1067 | 206.914 | 138.911 | |

| 9.525 | 0.0375 | 248.319 | STD | 166.708 | |||

| 12.700 | 0.0500 | 33.097 | XHY | 221.610 | |||

| 19.050 | 0.0750 | 492.163 | 330.0413 | ||||

| 48″ | 9.525 | 0.0375 | 48.000 | 1219 | 284.112 | STD | 190.0738 |

| 11.125 | 0.0438 | 331.404 | 222.487 | ||||

| 12.700 | 0.0500 | 377.822 | XHY | 253.650 | |||

| 19.050 | 0.0750 | 563.750 | 378.473 | ||||

| 22.225 | 0.0875 | 655.969 | 440.0383 | ||||

Copper Nickel Pipes Pressure Ratings

| Pipes O.D. in. |

Wall Thickness of Pipe (inches) | |||||||||

| .028 | .030 | .035 | .049 | .065 | .083 | .095 | .109 | .120 | 0.134 | |

| Working Pressure (psig) | ||||||||||

| 1/8 | 2700 | 3000 | 3600 | |||||||

| 3/16 | 1800 | 1900 | 2300 | 3400 | ||||||

| 1/4 | 1300 | 1400 | 1600 | 2700 | 3500 | |||||

| 5/16 | 1300 | 2200 | 2700 | |||||||

| 3/8 | 1000 | 1600 | 2200 | |||||||

| 1/2 | 800 | 1100 | 1600 | 2100 | ||||||

| 5/8 | 900 | 1200 | 1600 | 1900 | ||||||

| 3/4 | 700 | 1000 | 1300 | 1500 | 1800 | |||||

| 7/8 | 600 | 800 | 1100 | 1300 | 1500 | |||||

| 1 | 500 | 700 | 900 | 1100 | 1300 | 1500 | ||||

| 1 1/8 | 600 | 800 | 1000 | 1100 | 1300 | 1400 | ||||