OTHER PRODUCTS

Have Questions?

Get in touch with us today to avail the best quote for your requirement. We offer top quality metal products, competitive pricing and quick delivery.

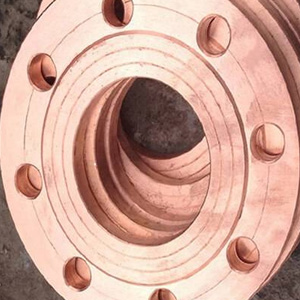

Copper Nickel Flanges

Copper Nickel Alloy Forged Flanges, Copper Nickel Socket Weld Flanges, ASME SB564. Supplier of Copper Nickel Lap Joint Flanges, ASTM B564. Copper Nickel Threaded Flanges, Copper Nickel Orifice Flanges, Cupronickel 70/30 Ring Joint Flanges, Copper Nickel Alloy UNS C70600 Plate Flanges, Copper Nickel 70/30 WNRF Flanges Manufacturer, Copper Nickel UNS C71500 Flanges, Copper Nickel 90/10 Flanges Cupronickel 90/10 RTJ Flange, Copper Nickel Spacer Flange, and Copper Nickel Lap Joint Flanges Supplier.

Overview

Dhodi Metal Industries is one of the leading manufacturers, suppliers, and exporters of Copper Nickel Alloy Flanges. We offer these pipe flanges in a variety of shapes, sizes, diameters, material grades, and other criteria. We manufacture Copper Nickel Alloy Flanges using high-quality materials and modern manufacturing procedures and offer them to both domestic and worldwide markets.

Copper Nickel 90/10 and 70/30 alloy flanges are indeed well-regarded for their unique properties, making them highly suitable for demanding environments like seawater systems, desalination plants, and marine engineering. Copper Nickel 90/10 Alloy Flanges are very resistant to seawater corrosion because to the high manganese and iron content. Similarly, Copper Nickel 70/30 Alloy Flanges are highly durable and resistant to heat and corrosion. We make a wide range of flanges, including Copper Nickel Slip On Flanges, Copper Nickel Orifice Flanges, Copper Nickel Threaded Flanges, Copper Nickel Spacer Flanges, Copper Nickel Lap Joint Flanges, and more.

Copper nickel flanges are integral parts of piping systems, often used to connect pipes, valves, pumps, and other equipment. Known for their high resistance to corrosion, especially in seawater and marine environments, copper nickel flanges are favored in industries like marine, desalination, oil and gas, and power generation.

Copper nickel flanges are typically made from two main grades of copper-nickel alloys: Cu-Ni 90/10: Composed of 90% copper and 10% nickel, suitable for seawater applications and less demanding environments. Cu-Ni 70/30: Composed of 70% copper and 30% nickel, offering superior strength and corrosion resistance, particularly in harsh marine environments.

Common Types of Copper Nickel Flanges:

- Copper Nickel Weld Neck Flanges: These flanges have a long tapered hub and are welded to the pipe. They are ideal for high-pressure applications.

- Copper Nickel Slip-On Flanges: Slip over the pipe and are welded both inside and outside for a secure fit. Commonly used in low-pressure applications.

- Copper Nickel Socket Weld Flanges: Have a recessed area where the pipe fits into, and a single fillet weld is used to connect the flange and pipe.

- Copper Nickel Blind Flanges: Used to close off piping systems or vessels and can be removed when needed for maintenance.

- Copper Nickel Lap Joint Flanges: Work with stub end fittings and are used in systems where frequent dismantling is needed.

- Copper Nickel Threaded Flanges: Threaded to attach to pipes without welding, commonly used in lower pressure applications.

Specification Of Copper Nickel Flanges

| Standard Specification | ANSI-B16.5, DIN-86037, BS-1560, MSS-SP-44, B16.47A/B, EEMUA-145, ASTM / ASME SB 61 / 62 / 151 / 152, EN1092-1, BS 10 TABLE FLANGES, AWWA, BS4504, BS3293, JIS, DIN |

| Grades | Copper Nickel 90/10 Flanges (C70600 ), Cupro Nickel 70/30 Flanges (C71500), UNS C71640 |

| Size | 1/2″ 36″ |

| Class / Pressure | 2500#, 1500#, PN25, 600#, 150#, PN6, 300#, PN64, PN10, 900#, PN40, PN16 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| Flange Type | Ring, Disk, Plate, Weld-Neck, Slip-On, Socket-Weld, Lap-Joint, Orifice, Reducing, Blind, Loose, Thread etc. |

| Pressure Rating | 10Bar, 14BAR, 16BAR, 20BAR, Class 150, 300, 400, 600, 900, 1500, 2500, PN10, PN14 |

| Manufacturing size range of Copper Nickel Flange | 1/2″ up to 36″ |

| Thickness | 5s to XXS |

| Material Test Certificates (MTC) | All Copper Nickel Flange material supplied with MTC EN 10204 3.1, 3.2 |

| Flange Face | TG, M, F, FF, RTJ, MF, G, T, RF |

| Flange Size | DN10—DN2000, or Customized as per customer Drawing |

| Flange Pressure | 150 – 20000 LBS, PN6 – PN400 |

| Copper Nickel Flanges Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

Cupro Nickel Flanges Types

-

- Copper Nickel Slip-On Flanges

-

- Copper Nickel Threaded Flanges

-

- Copper Nickel Long Weld Neck Flanges

-

- Copper Nickel Ring Type Joint Flanges

-

- Copper Nickel Lap Joint Flanges

-

- Copper Nickel Socket weld Flanges

-

- Copper Nickel Weld Neck Flanges

-

- Copper Nickel Blind Flanges

Copper Nickel Flanges Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS |

| Copper Nickel 90/10 | 2.0872 | C70600 |

| Copper Nickel 70/30 | 2.0882 | C71500 |

Copper Nickel Flanges Chemical Composition

| Grade | Cu | Pb | Mn | Fe | Zn | Ni |

| Cupro Nickel 90/10 | 88.6 min | .05 max | 1.0 max | 1.8 max | 1 max | 9-11 max |

| Cupro Nickel 70/30 | 65.0 min | .05 max | 1 max | 0.4-1.0 | 1 max | 29-33 |

Cupro-Nickel Flanges Physical Properties

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Cu-Ni 90/10 | 0.323 lb/in3 at 68 F | 2260 F | 50000 psi | 20000 psi | 30 % |

| Cu-Ni 70/30 | 0.323 lb/in3 at 68 F | 2260 F | 50000 psi | 20000 psi | 30 % |

Cupro Nickel Flanges Dimensions

| NPS (in.) |

Cupro Nickel Flange Dimensions | ||||

| Dia. of Flange (in.) |

No. of Bolts |

Dia. of Bolts (in.) |

Dia. of Bolt Holes (in.) |

Bolt Circle (in.) |

|

| 1/4 | 3-3/8 | 4 | 1/2 | 0.62 | 2-1/4 |

| 1/2 | 3-1/2 | 4 | 1/2 | 0.62 | 2-3/8 |

| 3/4 | 3-7/8 | 4 | 1/2 | 0.62 | 2-3/4 |

| 1 | 4-1/4 | 4 | 1/2 | 0.62 | 3-1/8 |

| 1-1/4 | 4-5/8 | 4 | 1/2 | 0.62 | 3-1/2 |

| 1-1/2 | 5 | 4 | 1/2 | 0.62 | 3-7/8 |

| 2 | 6 | 4 | 5/8 | 0.75 | 4-3/4 |

| 2-1/2 | 7 | 4 | 5/8 | 0.75 | 5-1/2 |

| 3 | 7-1/2 | 4 | 5/8 | 0.75 | 6 |

| 3-1/2 | 8-1/2 | 8 | 5/8 | 0.75 | 7 |

| 4 | 9 | 8 | 5/8 | 0.75 | 7-1/2 |

| 5 | 10 | 8 | 3/4 | 0.88 | 8-1/2 |

| 6 | 11 | 8 | 3/4 | 0.88 | 9-1/2 |

| 8 | 13-1/2 | 8 | 3/4 | 0.88 | 11-3/4 |

| 10 | 16 | 12 | 7/8 | 1 | 14-1/4 |

| 12 | 19 | 12 | 7/8 | 1 | 17 |

| 14 | 21 | 12 | 1 | 1.12 | 18-3/4 |

| 16 | 23-1/2 | 16 | 1 | 1.12 | 21-1/4 |

| 18 | 25 | 16 | 1-1/8 | 1.25 | 22-3/4 |

| 20 | 27-1/2 | 20 | 1-1/8 | 1.25 | 25 |

| 24 | 32 | 20 | 1-1/4 | 1.38 | 29-1/2 |

Cupro-Nickel Flanges Size Chart

| Nominal Pipe Size | Outside Diameter of Flanges | Thickness of Flanges | Diameter of Raised Face | Diameter of Hub at Base | Length Thru Hub | Diameter or Bore | Diameter of Hub at Bevel | Radius of Fillet | Depth of Socket | |||

| Welding Neck | Slip-On Threaded Socket | Lap Joint | Slip-on Socket | Lap Joint | ||||||||

| O | Q | R | X | Y | Y | Y | W | B | H | r | Z | |

| 1/2 | 3-1/2 | 7/16 | 1-3/8 | 1-3/16 | 1-7/8 | 5/8 | 5/8 | .88 | .90 | .84 | 1/8 | 3/8 |

| 3/4 | 3-7/8 | 1/2 | 1-11/16 | 1-1/2 | 2-1/16 | 5/8 | 5/8 | 1.09 | 1.11 | 1.05 | 1/8 | 7/16 |

| 1 | 4-1/4 | 9/16 | 2 | 1-15/16 | 2-3/16 | 11/16 | 11/16 | 1.36 | 1.38 | 1.32 | 1/8 | 1/2 |

| 1-1/4 | 4-5/8 | 5/8 | 2-1/2 | 2-5/16 | 2-1/4 | 13/16 | 13/16 | 1.70 | 1.72 | 1.66 | 3/16 | 9/16 |

| 1-1/2 | 5 | 11/16 | 2-7/8 | 2-9/16 | 2-7/16 | 7/8 | 7/8 | 1.95 | 1.97 | 1.90 | 1/4 | 5/8 |

| 2 | 6 | 3/4 | 3-5/8 | 3-1/16 | 2-1/2 | 1 | 1 | 2.44 | 2.46 | 2.38 | 5/16 | 11/16 |

| 2-1/2 | 7 | 7/8 | 4-1/8 | 3-9/16 | 2-3/4 | 1-1/8 | 1-1/8 | 2.94 | 2.97 | 2.88 | 5/16 | 3/4 |

| 3 | 7-1/2 | 15/16 | 5 | 4-1/4 | 2-3/4 | 1-3/16 | 1-3/16 | 3.57 | 3.60 | 3.50 | 3/8 | 13/16 |

| 3-1/2 | 8-1/2 | 15/16 | 5-1/2 | 4-13/16 | 2-13/16 | 1-1/4 | 1-1/4 | 4.07 | 4.10 | 4.00 | 3/8 | 7/8 |

| 4 | 9 | 15/16 | 6-3/16 | 5-5/16 | 3 | 1-5/16 | 1-5/16 | 4.57 | 4.60 | 4.50 | 7/16 | 15/16 |

| 5 | 10 | 15/16 | 7.5/16 | 6-7/16 | 3-1/2 | 1-7/16 | 1-7/16 | 5.66 | 5.69 | 5.56 | 7/16 | 15/16 |

| 6 | 11 | 1 | 8-1/2 | 7-9/16 | 3-1/2 | 1-9/16 | 1-9/16 | 6.72 | 6.75 | 6.63 | 1/2 | 1-1/16 |

| 8 | 13-1/2 | 1-1/8 | 10-5/8 | 9-11/16 | 4 | 1-3/4 | 1-3/4 | 8.72 | 8.75 | 8.63 | 1/2 | 1-1/4 |

| 10 | 16 | 1-3/16 | 12-3/4 | 12 | 4 | 1-15/16 | 1-15/16 | 10.88 | 10.92 | 10.75 | 1/2 | 1-5/16 |

| 12 | 19 | 1-1/4 | 15 | 14-3/8 | 4-1/2 | 2-3/16 | 2-3/16 | 12.88 | 12.92 | 12.75 | 1/2 | 1-9/16 |

| 14 | 21 | 1-3/8 | 16-1/4 | 15-3/4 | 5 | 2-1/4 | 3-1/8 | 14.14 | 14.18 | 14.00 | 1/2 | 1-5/8 |

| 16 | 23-1/2 | 1-7/16 | 18-1/2 | 18 | 5 | 2-1/2 | 3-7/16 | 16.16 | 16.19 | 16.00 | 1/2 | 1-3/4 |

| 18 | 25 | 1-9/16 | 21 | 19-7/8 | 5-1/2 | 2-11/16 | 3-13/16 | 18.18 | 18.20 | 18.00 | 1/2 | 1-15/16 |

| 20 | 27-1/2 | 1-11/16 | 23 | 22 | 5-11/16 | 2-7/8 | 4-1/16 | 20.20 | 20.25 | 20.00 | 1/2 | 2-1/8 |

| 24 | 32 | 1-7/8 | 27-1/4 | 26-1/8 | 6 | 3-1/4 | 4-3/8 | 24.25 | 24.25 | 24.00 | 1/2 | 2-1/2 |

Cupro-Nickel Flanges Weight Chart

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub |

Diameter of Raised Face | Length Hub.Y | Thread Length | Diam. of Bolt Circle |

Diam. of Bolt Holes |

Number of Bolts |

Diam. of Bolts (inch) |

KG | LB | |

| inch | dn | O | C | X | G | Y | T | BC | BH | BN | BD | ||

| 1/2″ | 15 | 89.00 | 11.20 | 30.20 | 35.10 | 15.70 | 15.70 | 60.50 | 15.80 | 4 | 1/2″ | 0.4 | 0.9 |

| 3/4″ | 20 | 98.50 | 12.70 | 38.10 | 42.90 | 15.70 | 15.70 | 69.90 | 15.80 | 4 | 1/2″ | 0.7 | 1.5 |

| 1″ | 25 | 108.00 | 14.20 | 49.30 | 50.80 | 17.50 | 17.50 | 79.30 | 15.80 | 4 | 1/2″ | 0.8 | 1.8 |

| 1-1/4″ | 32 | 117.50 | 15.70 | 58.70 | 63.50 | 20.60 | 20.60 | 88.90 | 15.80 | 4 | 1/2″ | 1.2 | 2.6 |

| 1-1/2″ | 40 | 127.00 | 17.50 | 65.00 | 73.20 | 22.40 | 22.40 | 98.60 | 15.80 | 4 | 1/2″ | 1.5 | 3.3 |

| 2″ | 50 | 152.50 | 19.10 | 77.70 | 91.90 | 25.40 | 25.40 | 120.70 | 19.10 | 4 | 5/8″ | 2.3 | 5.1 |

| 2-1/2″ | 65 | 178.00 | 22.40 | 90.40 | 104.60 | 28.40 | 28.40 | 139.70 | 19.10 | 4 | 5/8″ | 3.7 | 8.1 |

| 3″ | 80 | 190.50 | 23.90 | 108.00 | 127.00 | 30.20 | 30.20 | 152.40 | 19.10 | 4 | 5/8″ | 4.1 | 9 |

| 3-1/2″ | 90 | 216.00 | 23.90 | 122.20 | 139.70 | 31.80 | 31.80 | 177.80 | 19.10 | 8 | 5/8″ | 5.1 | 11.2 |

| 4″ | 100 | 228.50 | 23.90 | 134.90 | 157.20 | 33.30 | 33.30 | 190.50 | 19.10 | 8 | 5/8″ | 5.9 | 13 |

| 5″ | 125 | 254.00 | 23.90 | 163.60 | 185.70 | 36.60 | 36.60 | 215.90 | 22.40 | 8 | 3/4″ | 7 | 15.4 |

| 6″ | 150 | 279.50 | 25.40 | 192.00 | 215.90 | 39.60 | 39.60 | 241.30 | 22.40 | 8 | 3/4″ | 8.4 | 18.5 |

| 8″ | 200 | 343.00 | 28.40 | 246.10 | 269.70 | 44.50 | 44.50 | 298.50 | 22.40 | 8 | 3/4″ | 13 | 28.6 |

| 10″ | 250 | 406.50 | 30.20 | 304.80 | 323.90 | 49.30 | 49.30 | 362.00 | 25.40 | 12 | 7/8″ | 18 | 39.5 |

| 12″ | 300 | 482.50 | 31.80 | 365.30 | 381.00 | 55.60 | 55.60 | 431.80 | 25.40 | 12 | 7/8″ | 29 | 64 |

| 14″ | 350 | 533.50 | 35.10 | 400.10 | 412.80 | 57.20 | 57.20 | 476.30 | 28.50 | 12 | 1″ | 39 | 86 |

| 16″ | 400 | 597.00 | 36.60 | 457.20 | 469.90 | 63.50 | 63.50 | 539.80 | 28.50 | 16 | 1″ | 47 | 103 |

| 18″ | 450 | 635.00 | 39.60 | 505.00 | 533.40 | 68.30 | 68.30 | 577.90 | 31.80 | 16 | 1 1/8″ | 57 | 126 |

| 20″ | 500 | 698.50 | 42.90 | 558.80 | 584.20 | 73.20 | 73.20 | 635.00 | 31.80 | 20 | 1 1/8″ | 76 | 167 |

| 24″ | 600 | 813.00 | 47.80 | 663.40 | 692.20 | 82.60 | 82.60 | 749.30 | 35.10 | 20 | 1 1/4″ | 97 | 214 |