OTHER PRODUCTS

Have Questions?

Get in touch with us today to avail the best quote for your requirement. We offer top quality metal products, competitive pricing and quick delivery.

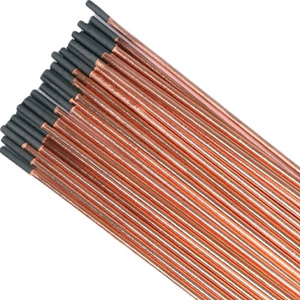

Copper Nickel Welding Rods

Copper-Nickel, Cu7061, CuNi10, SG-CuNi10Fe, Welding Wire CuNi 90/10 Filler Wire, Cu Ni 90/10 Welding Filler Wire, 90/10 Cupro Nickel Filler Wire, Cu-Ni 90/10 Filler Wire, Cupro Nickel 90/10 Filler Wire Manufacturers, Cupro Nickel 90/10 Welding Wire, Cupro Nickel 90/10 Filler Wire Supplier, Copper Nickel 90/10 Welding Rods Supplier in Mumbai, India.

Overview

Dhodi Metal Industries Manufacturer & Suppliers of Copper-Nickel (Cu-Ni) Welding rods which are specialized consumables used in welding copper-nickel alloys, which are commonly chosen for their high corrosion resistance, particularly in marine environments. These alloys are widely used in applications like shipbuilding, desalination, offshore oil and gas, and cooling systems.

Our Copper Nickel (CuNi) welding rods are precision built to deliver peak performance in both TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding applications.

Additionally, these rods are very resistant to corrosion and biofouling in seawater. Copper Nickel Tig Welding Rods have been successfully utilized in seawater for more than 50 years. Cupro Nickel Tig Rod’s molecular formula is CuNi. Its annealed tensile strength is 52000 psi (359 MPa), and its rolled-H04 (for flat items) or hard-drawn-H80 (for tubing) tensile strength is 78000 psi (538 MPa). It’s important to remember that most common welding techniques can be used to weld copper nickel in copper nickel pipe. When copper nickel brazing rods are rolled (H04 for flat goods) or hard drawn (H80 for tubing), their elongation at break is 11%, and when they are annealed, it is 40%.

Types of Copper-Nickel Alloys in Welding

- CuNi 70/30 (70% copper, 30% nickel): Known for excellent resistance to seawater corrosion and erosion, it’s more corrosion-resistant than the 90/10 alloy.

- CuNi 90/10 (90% copper, 10% nickel): Offers good corrosion resistance and is more cost-effective. This alloy is easier to weld and still performs well in marine environments.

Key Properties

Copper-nickel welding rods, like the alloys they’re used for, exhibit:

- High resistance to seawater corrosion and biofouling: Essential for marine and offshore applications.

- Good thermal conductivity: Important in heat exchangers and cooling systems.

- Resistance to stress corrosion cracking: Beneficial in harsh conditions where structural integrity is critical.

Specification of Cupro Nickel Welding Rods

| Welding Process | Form | Type | AWS Spec | BS Spec |

| MMA | Flux-coated | Cu-30% Ni | A5.6 ECuNi | In draft |

| (SMAW) | electrodes | |||

| 65% Ni-Cu | A5.11 ENiCu-7 | BS EN ISO 14172 | ||

| E Ni4060 | ||||

| TIG (GTAW) | Wire in | Cu-30% Ni | A5.7 ERCuNi | BS EN ISO 24373 |

| MIG (GMAW) | straight | S Cu 7158 | ||

| lengths or spools | 65% Ni-Cu | A5.14 ERNiCu-7 | BS EN ISO 18274

S Ni 4060 |

Cupro Nickel Bars & Rods Types

-

- Cupro Nickel Welding Rods

-

- Cupro Nickel Fillers wires & Rods

-

- Cupro Nickel Welding Electrodes

-

- Cupro Nickel Brazing Rods

Copper Nickel Welding Rode International Standard Codes

| Grade | UNS | DIN | ISO | BSI | ASME | ASTM | MIL | SAE | EEMUA | AWS |

| CuNi 90/10 | C70600 | 2.0872 | CuNi10Fe1Mn | CN102 | SB 466 | B466 | MIL-T-16420K | J461 | 144 | A5.7 ERCuNi |

| CuNi 70/30 | C71500 | 2.0882 | CuNi30Mn1Fe | CN107 | SB 466 | B466 | MIL-T-15005 | J461 | 146 | A5.7 ERCuNi |

Copper Nickel Welding Rods Chemical Composition

| Cu | bal. |

| Fe | 0.40 – 0.70 |

| Mn | 0.50 – 1.50 |

| Ni | 29.00 – 32.00 |

| P | 0.020 |

| Pb | 0.020 |

| Si | 0.25 |

| C | 0.040 |

| Ti | 0.20 – 0.50 |

| S | 0.010 |

| Others | 0.50 |

Cu-Ni Welding Rods Working Specification

| specification(mm)dia. x length | working current(A) | Packing | weight |

| 4×355 | 200 | 200PCS | 1.56Kg |

| 5×355 | 255 | 100PCS | 1.22Kg |

| 6×355 | 325 | 50PCS | 0.92Kg |

| 7×355 | 350 | 50PCS | 1.20Kg |

| 8×355 | 400 | 50PCS | 1.6Kg |

| 10×355 | 550 | 50PCS | 2.32Kg |